What is spider concrete placing boom?

Spider Concrete placing boom is a product developed for enlarging the range of concrete pouring and improving the mechanization level of pumping construction. Being corollary equipment of concrete pump, it increases the range of concrete pumping by connecting with concrete pump; also, in effectively solving the hard problem of material distribution in wall pouring, it plays an important role in increasing construction efficiency and reducing labor intensity.

Brief introduction of spider concrete placing boom

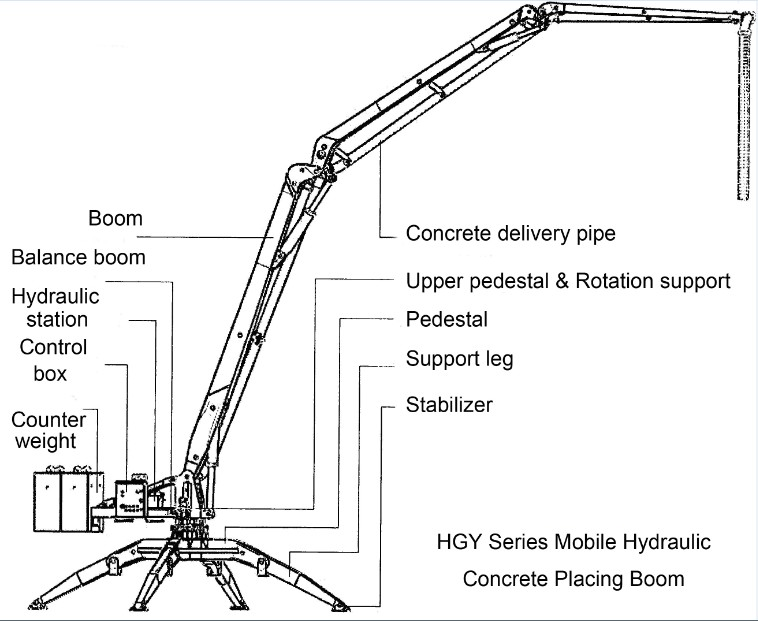

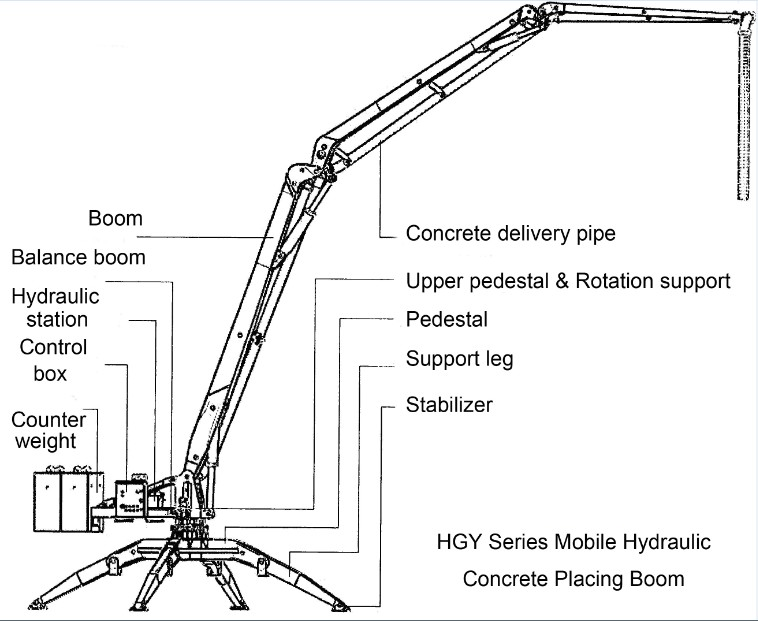

HGY series concrete placing boom is composed of boom assembly, slewing mechanism, lower frame, rear support, counterweight, concrete pipeline, hydraulic system and electrical control system. The extension and folding of the three-section arm is controlled by the hydraulic system, and the end of the concrete conveying pipe can be extended to the construction point that needs to be poured in coordination with the rotating action of the slewing mechanism.

HGY series placing machine adopts concrete conveying pipe with nominal inner diameter of Φ125mm.

spider concrete placing boom

spider concrete placing boom

The hydraulic system is equipped with a safety relief valve to prevent overloading of the working mechanism. Hydraulic locks are installed on the working cylinders to ensure construction safety.

The electrical control system can realize control cabinet panel operation and wired remote control operation. There are interlocks between each operation mode to ensure construction safety.

This equipment needs to be hoisted in place by means of a crane. Before hoisting, it should be confirmed whether the hoisting performance of the crane meets the requirements.

In addition, we have developed and designed a mobile concrete placer boom with wheels and hydraulic outriggers, which makes it easier to move around the floor.

How many models spider concrete placing boom are there in HAMAC?

HAMAC provide you with the full series hydraulic spider concrete placing boom HGY13, HGY15, HGY17, HGY21. The number stands for the working radius of the placing boom. It also can be understand as the length of the boom. You can choose the suitable model according to the length and width of the building.

What are the advantages of mobile spider concrete placing boom?

1.Reasonably designed, with stable and reliable structure,

2.The whole machine can be easily operated and flexibly turned due to its all direction and boom-type distributing structure,

3.High efficiency and energy-saving, as well as being economical and practical, etc.

4.It can be moved by the tower crane, its weight is strictly designed according to the capability of tower crane;

5.It can be equipped with wheels to instead of the support legs, then it can be moved easily without tower crane;

Which kind of project to use the spider concrete placing boom?

Normally speaking, it is used for some building floors which is not so big occupation. It can be moved by a tower crane, that means, its weight is less than the maximum load of the tower crane which is installed onsite. So, it is also called as mobile concrete placing boom. After the concrete pouring work in the floor is finished, the spider concrete placer will be lifted by the tower crane and moved to another higher floor or another place.

What is the capacity of spider concrete placing boom?

Many clients ask this questions. Hereby, please note that spider concrete placing boom is only a tools which is connected with trailer concrete pump or concrete line pump, its usage is only to pour the concrete to different positions. So, it has not any information of capacity. The capacity is related to the concrete pumps which is connected with the mobile concrete placing boom.

Features of mobile spider concrete placing boom of HAMAC

1. The spider concrete placing boom for sale does not need to be fixed when it is used.

2. It can be placed flexibly according to the needs of the construction site;

3. The mobile concrete placer boom has stable structure and light weight, which can be hoisted and transported by the whole machine.

4. It adopts 360° full-rotation boom type fabric structure, the whole machine is easy to operate, flexible to rotate,

5. It has the characteristics of energy saving, economy and practicality, and plays a major role in improving construction efficiency and reducing labor intensity.

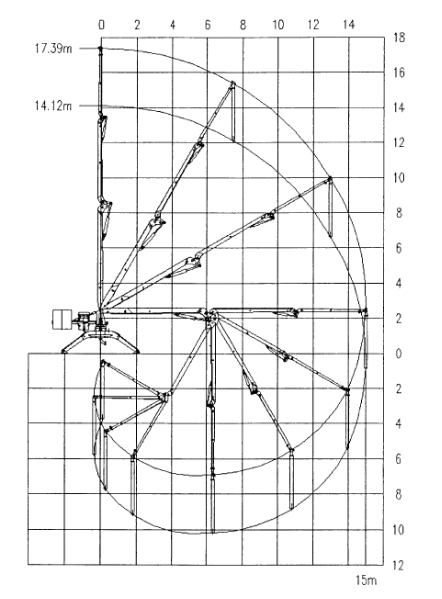

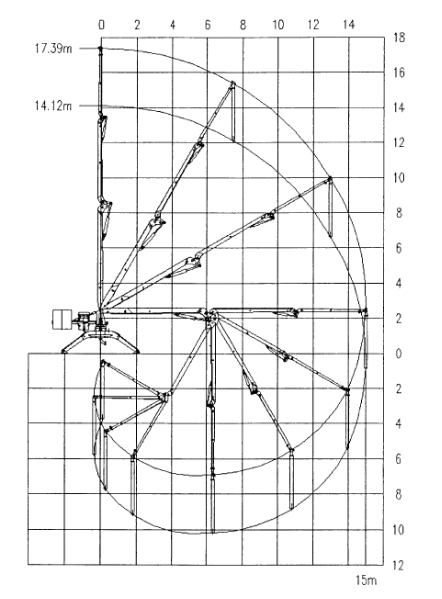

Working range diagram of the spider concrete placing boom

We take HGY15 as a sample to show you how to understand its working range.

Working range diagram of the spider concrete placing boom

How much is the spider concrete placing boom?

For the spider concrete placing boom, its price range is between USD2000-USD40000 according to different models and types. Please contact us to get the exact price.

Factors needs to be considered to buy a spider concrete placing boom

If you want to buy a spider concrete placing boom, you have to consider the below conditions,

1.What is the length and width of the building floor? To see if the length and width are in its working radius range;

2.Is there a tower crane there? It will be used to life the mobile concrete placing boom to different potions and different floors;

3.What is your budget? You have to calculate the CIF price and customs tax together to see the final price in your country;

How to maintain the spider concrete placer boom after working?

It is very important to maintain the concrete placing boom after working. You have to wash the concrete in the pipeline, a sponge ball will be insert into the cylinder of concrete pump and then pumped together with water, finally the sponge ball will come out from the end of pipe of concrete placing boom. After this, the concrete in the pipe will be cleaned.

Meanwhile, you have to lubricate the machine, check the level of hydraulic oil etc.

33m self-climbing concrete placing boom works in Malaysia

33m self-climbing concrete placing boom works in Malaysia

This concrete placing boom is purchased by a company in Malaysia but headquarter in Australia. After visiting several famous brands in China, finally they choose HAMAC as their supplier because they checked our factory and see our production procedure with strict quality control system.