| MODEL |

LOADING CAPACITY cu. yd. / cu.m. |

COMPACTED YIELD cu. yd. / cu.m. |

PAN DIAMETER inch / mm |

MIXING MOTOR HP / KW |

SKIP MOTOR HP / KW |

HYDRAULIC POWER PACK HP / KW |

SPEED rpm |

MIXING ARMS |

WEIGHT (without skip) lb / kg |

WEIGHT (with skip) lb / kg |

| MP 75/50 | 0.1 / 0.075 | 0.07 / 0.05 | 28/700 | 2 / 1.5 | 0.75/0.55 | 1/0.75 | 22 | 3 | 441 / 200 | 882 / 400 |

| MP 150/100 | 0.2 / 0.15 | 0.13 / 0.1 | 39/1000 | 5.5 / 4 | 1/0.75 | 1/0.75 | 19 | 3 | 1102 / 500 | 1984 / 900 |

| MP 375/250 | 0.5 / 0.375 | 0.3 / 0.25 | 50/1260 | 10 / 7.5 | 2/1.5 | 2/1.5 | 19 | 3 | 2090 / 950 | 3080 / 1400 |

| MP 565/375 | 0.8 / 0.565 | 0.5 / 0.375 | 62/1580 | 15 / 11 | 3/2.2 | 2/1.5 | 19 | 3 | 3086 / 1400 | 4409 / 2000 |

| MP 750/500 | 1.0 / 0.75 | 0.7 / 0.5 | 72/1820 | 25 / 18.5 | 5.5/4 | 2/1.5 | 21 | 3 | 4409 / 2000 | 5953 / 2700 |

| MP1125/750 | 1.5 / 1.125 | 1.0 / 0.75 | 79/2000 | 40 / 30 | 7.5/5.5 | 3/2.2 | 20 | 3 | 5962 / 2700 | 8157 / 3700 |

| MP1500/1000 | 2.0 / 1.5 | 1.3 / 1.0 | 87/2200 | 60 / 45 | 10/7.5 | 5.5/4 | 21 | 3 | 7920 / 3600 | 10803 / 4900 |

| MP1875/1250 | 2.5 / 1.875 | 1.7 / 1.25 | 94/2400 | 60 / 45 | 10/7.5 | 5.5/4 | 15 | 6 | 10,362 / 4700 | 13008 / 5900 |

| MP2250/1500 | 3.0 / 2.25 | 2.0 / 1.5 | 102/2600 | 2×40/30 | 15/11 | 5.5/4 | 15 | 6 | 13,889 / 6300 | 18520 / 8400 |

| MP3000/2000 | 4.0 / 3.0 | 2.7 / 2.0 | 135/3420 | 2×50/37 | 2×15/2×11 | 7.5/5.5 | 14 | 6 | 21,385 / 9700 | 26457 / 12000 |

| MP3750/2500 | 5.0 / 3.75 | 3.3 / 2.5 | 135/3420 | 2×60/45 | 2×15/2×11 | 7.5/5.5 | 14 | 6 | 21,385 / 9700 | 26457 / 12000 |

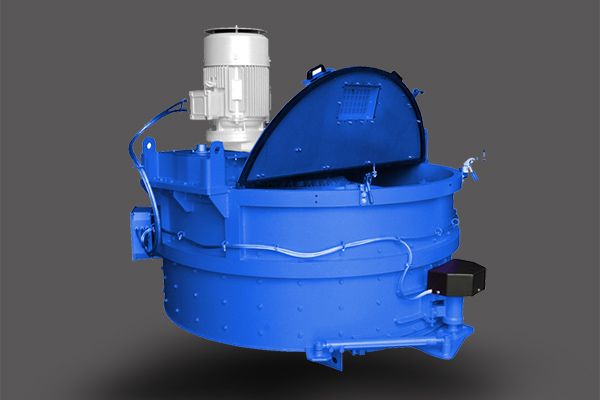

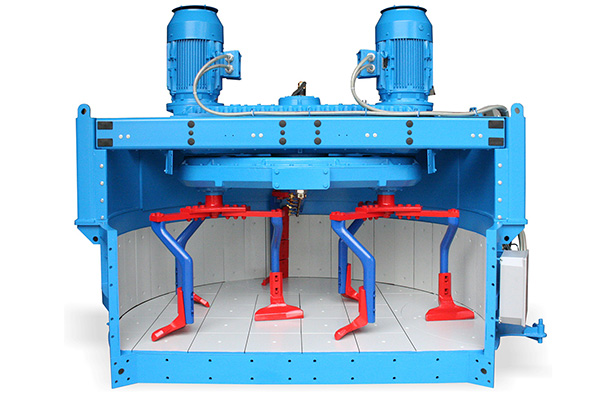

The excellent performance is recognized in the several application fields, in the Concrete Industry as well as Industrial Plants (waste treatment, chemical industry, glass industry). Depending on the type of application, all mixers can be equipped with several accessories and customized with many add-ons in order to achieve specific productivity, mixing quality and life expectancy requested in a certain field.

Application industry: Concrete / Cement Products (Blocks, Pavers, Curbstones, Sleepers, Pipes, Rings), Precast Elements (Beams, Hollow Core, Safety Barriers, Wall Panels) ,Dam Construction, Road Paving, Industrial Floors, Architectural Precast, Waste Treatment, Foundries, Glass Industry, Mine Industry (muds treatment, backfilling),Soil Stabilization, Fertilizers

Type of Mixed Product: Ready-mix concrete, Precast Concrete, Dry Cast, Roller Compacted Concrete (RCC), Self-Compacting Concrete (SCC), Fiber Reinforced Concrete, Lightweight Concrete, Backfilling, Inertization

Please Contact Us for your specific application – We provide solutions for each application.